Add to Cart

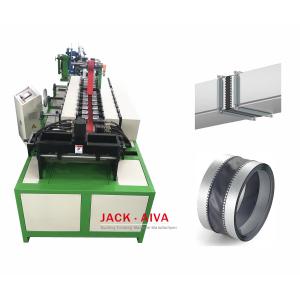

Production Line to manufacture HVAC Duct flexible connectors

The automatic flexible duct connector production Line is consisted of de-coiler, hydraulic punching, roll former and notching, cutter then the belt recoiling. If client has the large quantity production about the flexible duct connectors, this is the proper solution. The final products included punching anger and cutter all can be finished by one line.

The normal raw material of Flexible duct connector are the GI steel sheet and Fire-Resistant Fabric GC-PV (Polyester Vinyl), GC-SI(Silicone),GC-NE(Neoprene),GC-CV(Canvas). It can be installed between fans or similar equipment.

Technology Flow - HVAC Duct Flexible Connector Machine

Duct flexible connector Roll Forming machine mainly consists of conic, guide equipment, leveling system, punching, roll forming system, cutting system, stacking equipment, hydraulic station, electrical control system.

Power Un-coiler (2sets)--- hydraulic holes punching -- Main Roll Former --- Notching & Cutter -- Re-coiler

Main Parameters- HVAC Duct Flexible Connector Machine

| ITEM | CONTENT |

| Raw material | GI STEEL DC51+Z; 0.4-0.8mm It can be designed according to client request. |

| Line speed | 5-7m/min |

| Forming roller stations | 12 stations x 2 (double line stations on main roll forming machine) |

| Forming Roller material | GCR15 as raw material ,hardness HRC60-62 after treatment, |

| Shaft material | Quality steel Ф40mm, 45# steel |

| Main motor | 3kw + 0.75kw |

| suit for material size |

|

| Main machine sizes | 3500*1300*1300mm |

| Weight | 2500kg |

HVAC Flexible Duct connector Application

The Flexible Duct Connector is designed to enable flexible joints of any size to be easily and economically formed in the

factory or on site. Flexible joints are installed between fans(or similar equipment) to prevent the transmission of vibration,

noise and rattles to the remainder of the air conditioning system.

Advantages

TAG: HVAC Duct Flexible Connector Machine, Duct Flexible Connector